THE T3 SYNCRO

WRITTEN BY SIMON HOLLOWAY

VW developed 4-wheel drive on both Beetles (Type 86 – Kommanderwagen) & (Type 128 “Schwimmwagens”) during the Second World War.

It took nearly another 40 years before they ventured into this field again.

During the 1970’s a couple of VW engineers who both liked to travel in their Westfalia campers to far off inhospitable regions of Africa & Europe decided it might be a good thing if VW revisited 4WD & developed some vehicles capable of getting further than existing models were able to & seriously competing with the existing 4WD market.

They were ideally placed to do this; Gustav Meyer ( 1925-2014) was head of VW Light truck engineering & Henning Duckstien was in charge of the truck testing department.

Money for research was tight in those days (as the T25 was being developed) but between them they managed to produce five prototype 4WD Bay window transporters using a lot of parts from other vehicles. The driver for this was that if VW could produce a good 4WD drive vehicle & be seen to be competing (or supplying support vehicles) for the tough African rallies then this would attract orders for transporters from the armed forces.

The first of the five prototypes was completed at the end of 1975. The vehicles had semi automatic gearboxes similar to the “Stick Shift” Beetles. These were coupled via a torque converter and a hydraulic clutch to a 70BHP 2-litre engine, which had just been developed for the VW/Audi military “Iltis” vehicle. The system had friction type diff locks & an extra lever in the cab allowed it to be driven in either 2 or 4 wheel drive. Extensive modification was required to the front axle to accommodate the differential & drive shafts (and rerouting of the heating system). These vehicles had drum brakes all round.

Under body plating was applied & the exhaust was modified (tailpipe through bumper!) to give extra ground clearance. Addition of 16” wheels also helped increase ground clearance.

The 5 prototypes undertook extensive testing & produced very positive results.

At the great european Syncro25years meeting, initiated by Busman, Mr Duckstein himself had a presentation of the testing of one of the prototypes in the Sahara.

Amazingly the VW marketing guru’s did not believe there was a market for 4WD utility vehicles in the future – not one of their best marketing decisions!!

Despite this Gustav & Henning managed keep their enthusiasm & continued the project.

At the launch of the Audi built “ Iltis” in 1978 a Bay 4WD prototype was also present. During trials before the German Armed Forces the Bay 4WD ran rings around the Iltis. Despite this the VW Chiefs still decided that the vehicle would not go into series production.

Significantly Ferdinand Piech, (then head of technology with Audi – later boss of VW) was at that demonstration & also saw other film & pictures of the prototypes performance during testing & during its expeditions to the Sahara & as a support vehicle for the Audi Quattro.

They also performed as well as they looked but unfortunately appeared at just the wrong time as VW’s attention had switched to the introduction of the T3.

At least one air-cooled T25 vehicle was produced in 1982 as a prototype expedition backup vehicle.

The introduction in 1983 of the water-cooled engined vehicles to the Type 25 range allowed VW to have another rethink about four-wheel drive.

This time though VW decided that they would not further develop their Bay Window 4WD design or even use the well tested “Quattro” system already installed on their sister companies Audi range.

Instead they went for a completely new and different “Ferguson” system (originally invented by a Briton) was used on Jensen cars and well tried out on the racetracks.

Volkswagen took this system to an Austrian company Steyr-Daimler-Puch, who were already well known in the four-wheel drive “field” for their “Haflinger” and Mercedes “G-Wagen” developments. This was part of a deal for which VW in return would supply LT Diesel engines for their “ Pinzgauer” 6x6 vehicles (that is something else in a different league)

Haflingers were once described to me by Richard Norman of the Haflinger Club (who uses a Syncro Pickup to transport his about) as being the most fun you can get with your trousers on. Its nearly true!

In the spring of 1985 the first Syncro Transporters started to appear.

Initially only 2 engine options were available; the 1.9 litre 78 bhp petrol & 1.6 litre 70bhp turbo diesel.

The 112 bhp 2.1 litre engine was still being developed & was introduced later for the 1986 model year just in time to go on sale in the UK. The 2.1 litre engine was also fitted with a catalyser on many vehicles. This reduced BHP to from 112 to 95.

The load and towing capability of these vehicles was very impressive. Road handling was/is just perfect. Once again VW managed to produce a perfectly balanced (50/50) vehicle. Something few vans produced today can boast.

Four-wheel drive versions of all models were available but sales were disappointing. There were several reasons for this.

Although the vehicle itself was exceptionally good it was expensive. This was mainly down to the logistics of the manufacturing process, which involved a lot of transportation. Initially, body shells from the Hanover works were delivered to the Steyer-Daimler-Puch works @ Graz in Austria to be fitted with their 4WD train. They were then shipped back to Hanover to be finished off. Vehicles destined to be campers were then shipped off again to the Westfalia works @ Wiedenbruk.

In the late 1980’s the entire T3 production line (including standard vehicles) was switched to the Graz works in Austria to make way for the introduction of the T4 Transporter due to start in the summer of 1990.

Some of these vehicles including Syncro’s were exported to be assembled as “Knock down Kits” in other locations (in particular Japan).

In the UK syncro models were £3500 - £3800 more expensive than the standard transporters which at a price of £13,000 - £15300 when introduced in 1986 made many people look elsewhere for cheaper vehicles.

Although the range of vehicles was very impressive they were let down by their engine range. The Syncro was a vehicle ideally suited & aimed at the service sector (in particular rescue services and the military).

Most of these services wanted much more powerful diesel engines than the pitiful 70 BHP offered by the golf turbo diesel unit being fitted to the VW transporter. Consequently sales of Syncro’s in this sector were very disappointing.

Of course, the one area that VW completely missed the boat was the leisure market. If their marketing department had seen what was coming I’m sure they would have continued to develop the vehicle and would now be the market leaders in 4WD utility vehicles rather than now trying again to get back into it with the Touareg, a “new luxury off roader” poor relation in people & load carrying practical terms compared with the Syncro!.

However Syncros continue to have their fans all over the world. Nowhere is this more fanatical than in Australia where they also have some ideal territory to test it to its limits.

In the early 1990’s the Syncros were very favoured rally vehicles.

It is ironic that when production of the T3 was continued in South Africa during the 1990’s they equipped it with the Audi 5 cylinder engine which gave the vehicle all the power it needed to really make it succeed. If this vehicle had then been made available in the at the right price then VW would almost certainly been have been the leader in the 4WD MPV market today.

One of the arguments for stopping production of the T3 in Germany was that the expensive boxer engines could not be used in their other (car) models it was been producing (as had been the case earlier with Beetles & Split Screens & Bay window Transporters).

It was quite acceptable however for the drive train from the Syncro to be incorporated into the VW car range. It was used in Golfs & Jetta’s but the only real attempt at making a true off road vehicle was when in 1989 the “Golf country” was produced. This vehicle has additional ground clearance & protection.

In 1993 a interesting military VW was produced. The “ COBRA” light strike vehicle. This vehicle used a mixture of VW components including (I believe) the Syncro drive train. Rear suspension though was old style trailing arms. It was powered by a 1.9 Turbo diesel

In the UK the Syncro vehicles, particually the Pickups & Crew Cabs were and still are firm favorites within the building trade. As far as utility firms are concerned it was the water companies that proved to be a good customer

The Syncro Ambulance conversion that is still on of the most utilised syncros still being used today. Rowan Medical Services has four Syncro ambulances & these can be seen at events all over the country (in particular Vanfest & BVF)

Of course the Syncro drive train was also used in the next generation of Transporters but the T4 Synco’s were never giventhe off road credentials of the T3.

SYNCRO TRANSPORTER PRODUCTION DETAILS

SYNCRO Total Production – 43468 (of these 2108 were right hand drive models)

Single Cab Pick ups (M245) 1787 produced.

These vehicles were only available in the UK with 1.9 litre petrol or 1.6 litre turbo diesels.

Double Cab Pickups (M247) 6849 produced.

These vehicles proved to be very popular & were generally available with the same engines as the pickup. However a special “Tristar” model was produced fitted with a 2.1 litre petrol engine.

Panel Vans (M251) 5848 Produced

These vehicles were available with all 3 engine formats

ENGINES – Fitted to SYNCROS

No Produced

2.1 (95 BHP Catalyser) 14,233

2.1 (112 BHP) 6259

1.9 (78BHP) 6641

1.6 Turbo Diesel (70BHP) 16335

Minibuses (M253) 14650 Produced

Many different types of minibus versions were available, ranging from 8 to 12 seats. They were however only supplied with the 1.9 petrol or 1.6 diesel & turbo diesel engines & were not available as Syncro’s in the UK.

Caravelles (M255) 14334 Produced

UK Supplied Caravelles were all fitted with 2.1 litre engines.

Syncro 16” (Option M855) 2138 Produced

Of the above vehicles, some were heavy duty special’s fitted with 16” Wheels. These were not generally available as export models but used by the service section within Germany. No 16” Wheeled vehicles were exported to the UK or US. Many different options were available on these vehicles. Most had different gear ratio’s, even heavier duty suspension & uprated brakes.

Tristar (M314) Unknown Number produced , estimated at 1000 syncro's and 500 2wd's

This was a special package based on the crewcab launched in October 1988. It came with alloy wheels, black wheel arch spats linked by graphite coloured lower body paint, an integrated spoiler plus twin rectangular headlights with washers plus most of the other equipment offered on the GL carravelle. Rear seat passengers also had their own heater.

A similar spec vehicle called the “Magnum” was produced for the German market.

Only a handful (if that!) of Tristars were sold in the UK. Where are they all now? Two dozens made it to the US.

Tristars in UK were available with either 2.1 litre or 1.6 litre Turbo diesel engines

Unfortunately very few of these vehicles were produced.

In the end VW were very keen to focus all their attention on the new T4 model & effectively killed off the T3 (and with it one of the best and versatile four wheel drive vehicles ever produced.)

HOW DOES IT WORK?

OK, so what is so special about a Syncro? Well they are probably one of the strongest and most versatile vehicles every produced & certainly the BEST VW Transporter ever made.

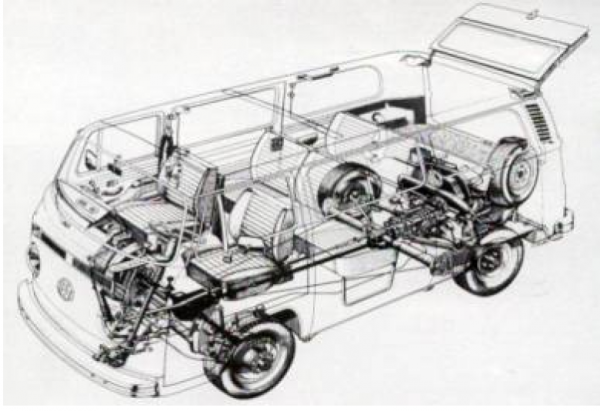

For those of you unfamiliar with the vehicle, it is fairly easy to spot once you start looking (hard). It sits about 25cm higher than a normal van (55cm if you are lucky enough to have a 16” Syncro). This is because the vehicle has its own sub frame to carry its 4-wheel drive system. Over the years this has confused many people who have not seen Syncros before & believed them to be customised vehicles. It is nice to be able to look down on Range Rovers!

Having four - wheel drive means that VW had to move some other bits about. The petrol tank was relocated to the rear over the gearbox & the spare wheel also had to be located inside the vehicle. The Syncro does have a special gearbox. In addition to an outlet to a drive shaft to the front differential (viscous coupling) it has 4 gears plus a very low ratio “ (G or Gelande – cross country) crawler gear” for any times you might be “inclined” to go or down extreme slopes.

To allow for the odd occasion that you might loose drive to both rear and/or the front wheels the Syncro was fitted with diff locks. Not all vehicles were fitted with both rear & front locks, but most if not all of the ones imported into the UK were. These are needed because, unlike more rugged of road vehicles the Syncro suspension & drives were not articulated enough & ride height still too low to avoid grounding out in the most extreme conditions.

The diff locks are basically vacuum operated solenoids which operate to lock either front or rear diffs (or both) They should not remain engaged during normal road use

The basic suspension system remains the same as the normal transporter although uprated springs & dampers are fitted. In the engine bay the Air cleaner was uprated to give better off road protection. Under the vehicle extra plating is fitted to protect the underside components of the vehicle. A very welcome (and often overlooked) addition fitted to the later Syncro was the rear window vents, which allowed a cool flow of air through the interior of the van without having to open the rear windows. Apart from that (& the four wheel drive system) most of the rest of the van is the same as a normal transporter.

How does the Syncro bit work? Well being a Volkswagen, the boffins decided that it had to be a simple system to use & work without the driver having to operate any extra controls for normal use on the road. That ruled out most conventional systems currently in use.

This is why they opted for the British Ferguson “FF” System.

This invention uses a viscous coupling instead of a central differential. This coupling comprises of a sealed drum shaped housing containing and cooled by a silicone liquid all built into the front differential unit. Inside the drum are two independent slotted & perforated sets of discs. One set is joined via a splined shaft to the prop shaft, which in turn connects to the gearbox. The other connects to the front final drive pinion.

The Silicone fluid flows between these discs & the only transmission of power between he discs occurs via that liquid when there is a difference in speed between drive & output of the rear wheels. When the rear wheels (significantly) loose grip or spin then the coupling locks and transfers drive to the front. The viscous drive coupling does allow slight differences in speed between front & rear.